Optimization of cannabis extraction yield by controlled milling

The Fritsch PULVERISETTE 19 is utilized to finely mill cannabis plant material in preparation for SFE processes. The efficient and precise reduction in particle size optimizes oil output and formulation.

The fast-growing field of cannabis extraction still holds many process inefficiencies, that can be easily overcome. A bottleneck often encountered is the packing density, or lack thereof, of cannabis plant material in the extraction vessel. Low packing density leads to a decrease in extraction efficiency and increase in output variability. Non-milled cannabis plant material generally experiences packing densities of 100-125 g/L, whereas milled material packs at 225-250 g/L.

The Fritsch PULVERISETTE 19 is an efficient tool to quickly comminute large volumes of cannabis plant material to a precise particle size. Plant material is fed into the PULVERISETTE 19 through large funnel for fast throughput. The negative pressure in the milling system ensures a continuous flow through the cutting rotor and the selected sieve cassette for precise particle sizing, and prevents any system clogging. The high throughput of up to 60 L/h is supported by large collection vessels of up to 10 liters. Fast processing is further supported by unrestricted accessibility of the cutting chamber, quickly removable cutting rotor and sieve cassette, and generally easy-to-clean grinding chamber.

In this application note we describe the general process employed at OutCo for sample preparation in their SFE production operation. This will include particle size distribution data and experimental data on extraction yield increases due to particle size reduction.

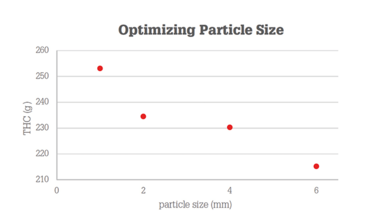

Figure 1: Extraction efficiency for different particle sizes. All other inputs are identical, e.g. type of material, weight of material (2.0 kg), and extraction parameters, like temperature (34˚C), pressure (124 bar), and run time (6 h).

After testing (Figure 1), we chose the 2mm screen size, as it allows for a high packing density, increased extraction speed, optimized oil constitution, while allowing the operator to constantly feed material into the mill itself, thus increasing work efficiency. The blade speed of 300 rpm was found to be optimal for narrow particle size distribution. Furthermore, this low blade speed avoids thermal damage and loss of volatiles for the sample. It is important that the moisture content of the material being milled is dry, below 15%, as the milling sieve will clog in the presence of moisture. One full extraction load of 4.5 kg can be milled before stopping the machine to clean the sieve and behind the milling wheel to prevent buildup of chlorophyll and cannabis residue. If there is not enough of a single cultivar to facilitate a full extraction run, a blend of strains can be homogenized using the Fritsch mill. Strains selected for a blend should have complimentary flavor profiles and can also be chosen to enhance therapeutic effects.

Other applications OutCo uses the mill for is sample preparation for rosin pressing and milling of flower for pre-roll production. It was found that different particle sizes optimize draw behavior or item stability.

The Fritsch PULVERISETTE 19 critically supports OutCo’s extraction operations by providing fast milling of powders with precise particle size distribution and minimal degradation of raw material.