Gurus of Pesticide Residue Analysis

The measurement of pesticides is challenging in itself, but with complex matrices, regulatory inconsistencies and the impact of heating and combustion, cannabis brings its own issues. As regulators in California and elsewhere tighten up pesticide testing rules, we speak to three top scientists about the analytical hurdles that need to be cleared – and the technology required to do it.

Meet the Gurus

Christopher Hudalla, Founder and CSO, ProVerde Laboratories, Massachusetts, USA

Chris worked for Waters Corporation for 14 years before establishing ProVerde Laboratories, Massachusetts, USA, in 2013. He is an experienced separation scientist, with a 25-year career focused on spectroscopic and chromatographic methods, including supercritical fluid chromatography (SFC) and convergence chromatography. He has been a tireless advocate for better quality and consistency for cannabis testing, and serves on a several committees to develop unified standards for the industry.

David Egerton, VP of Technical Services, CW Analytical, California, USA

With a BS and MS in Chemistry from the University of Louisville, David initially worked on tissue culture for a clone producer, before joining CW Analytical in 2011. As VP of Technical Services, he now spends his time developing better methods and has been liaising closely with Californian regulators about new testing regulations. David says, “The fun thing about this industry – and being an analytical chemist – is that you are constantly solving puzzles.”

Jingcun Wu, Senior Strategic Scientist, PerkinElmer, Canada

Jingcun has worked in analytical chemistry for over 25 years, both in industry and academia – including an adjunct professor position at the University of Waterloo, working with sample preparation pioneer Janusz Pawliszyn. Together with the team at PerkinElmer and a number of outside partners, he has developed methods to determine large numbers of pesticide residues in cannabis in a single run using LC-MS/MS.

How important is pesticide residue analysis in the cannabis industry?

Jingcun Wu: Pesticides, antifungals, and performance-enhancement reagents have been applied to cannabis, just as they are to other crops, to increase yields and prevent attacks from insects and mold. However, many of these chemicals and reagents may have harmful effects on humans, animals and the environment, especially people who grow or work with the products for a long period of time. In addition, when smoking plant materials such as tobacco and cannabis products, highly complex mixtures of compounds can be generated, many of which can interact with the chemicals (such as pesticides) present in the initial product to form even more toxic materials. Unsurprisingly, pesticide residues are found in the smoke produced by cannabis that has been grown using pesticides. So it’s important to have a highly sensitive and selective testing method for the analysis of pesticides and other toxic chemicals to control the quality of cannabis products and evaluate the risk to consumers.

Christopher Hudalla: I think it’s probably one of the most daunting and critical components of testing today. Because there has been a historical lack of regulation, people are using all sorts of pesticides. Plus, even pesticides that are considered safe for ingestion may have a very different safety profile after heating and combustion. A perfect example is the pesticide myclobutanil, which is extensively used in the cannabis industry. Myclobutanil is prevalent in the Californian environment because it’s used in wine grape cultivation, and has extremely low toxicity when ingested. The problem is that when it’s heated, the myclobutanil chemical structure decomposes, and one of the products is highly toxic hydrogen cyanide.

David Egerton: Although a lack of guidelines has definitely encouraged an “anything goes” mentality in the past, we’ve noticed in California that, as labs have shifted to higher-tech instruments, growers have responded by using fewer pesticides and gaining a better understanding of application rates and how persistent some of these compounds can be. It’s also market driven – there are a number of vendors out there that simply won’t buy any product that is contaminated with pesticides. Draft regulations for California have some of the lowest limits across the United States on cannabis products, which means it could be one of the first agricultural products to be mandated as truly organic. We’re certainly big advocates of pesticide testing, and a large portion of our business is QA testing for producers to ensure that their incoming feed is contaminant free – meaning the final product should be as well.

Mold can contaminate the crop, as well as damaging the plant.

How has pesticide residue analysis changed over the last decade?

JW: Traditionally, pesticides were analyzed mainly by GC-MS; however, ionic and polar compounds often require derivatization, and GC-MS is not suitable for thermally unstable compounds because of the high-temperature injector used in GC. In the last decade, more and more polar pesticides have been introduced, because they break down quickly and easily. The diversity of pesticides used in production has made multi-residue techniques the method of choice for more cost-effective and efficient analysis of pesticides in testing laboratories. With the advance of LC-MS/MS technology in the last couple of decades, especially the availability of ultra-high-performance liquid chromatography (UHPLC) and high acquisition speed mass spectrometers with fast polarity switching, UHPLC-MS/MS has become the go-to technology for multi-residue pesticide analysis in food and environmental fields – including cannabis.

DE: When testing laboratories were starting out, there was very little funding; many of the first labs simply didn’t have the budget to acquire a triple quad MS (or the inclination, as testing was voluntary). Hence, early analyses were largely based on very old methods, such as GC with electron capture detector or nitrogen-phosphorus detector, or single quad MS. Three or four years ago, many labs – including us – started to shift towards triple quads. That’s been the biggest innovation in the field, and it’s been quite the rollercoaster trying to reconcile all the methods developed in-house over the years, making sure all the labs are operating on an equal footing.

CH: As recently as four years ago, most testing in the cannabis industry was done for marketing purposes, to show that one product would get you more stoned than another. It was not a very robust testing environment... but it is changing dramatically. Everyone in the cannabis industry now realizes how critical testing is for patient and consumer safety. And as each new state implements testing regulations, they set a higher standard. Today, in many states, labs must be ISO 17025 accredited, which means they are forced to validate their methods and document their abilities. A test certificate saying “Avermectin: none detected” is meaningless if it doesn’t list the lower limit of sensitivity, or how it was measured – otherwise “none detected” could mean you sniffed it and didn’t smell any pesticides!

The grower’s friend: lacewings can act as natural pest control.

What are the main challenges in pesticide residue analysis – and how can we tackle them?

DE: As with many materials, the matrix is the problem. Unfortunately, cannabinoids elute from chromatographs at around the same time as the bulk of our pesticides. I have not found any solid phases that selectively remove pesticides from cannabis – so commercial cleanup technologies are not always the best solution. Furthermore, the breadth of the pesticides that the California regulations have asked us to detect not only necessitate using two instruments – the LC and GC triple quads – but can also create difficulties in designing multi-residue methods. Figuring out a sound chromatographic way to get around the interference created by the cannabinoids would certainly make pesticide analysis – and indeed, many of our other analyses – much easier. The dream for me would be a resin that’s specifically tailored to and would only bind cannabinoids – everyone in this industry would love that!

JW: I agree that the main analytical challenge is analyzing multi-pesticide residues at low levels from complex sample matrices. The most efficient approach for a testing lab is the use of multi-residue methods capable of determining many pesticides in one single run, but the differences in regulations among the states make it a challenge to have a single method that meets all the regulatory requirements. To overcome sample matrix effects, numerous tools have been applied to LC-MS/MS method development, such as sample dilution, use of stable isotope internal standards, sample matrix-matched standard calibration, standard addition method, sample clean-up, use of high efficiency UHPLC columns for better separation, and the use of alternative ionization sources. In my view, because of the diversity of sample matrices and the fact that the sample matrix without analytes is difficult to find, the dilute-and-shoot method is the simplest and most cost-effective approach to reduce matrix effects, although this methodology requires highly sensitive and robust instrumentation.

CH: Cost is also a factor – in terms of instrumentation, personnel, and consumables. Unfortunately, there are so many different classes of pesticides, analysis would typically require multiple pieces of instrumentation, most likely a liquid chromatograph or gas chromatograph with a triple quad mass spectrometer. To buy one of each costs close to $1m. Plus, as David mentioned, matrix interferences are a real problem – so you need highly skilled chemists who can distinguish between interferences and true pesticide contamination. You get what you pay for, and to do this right is expensive.

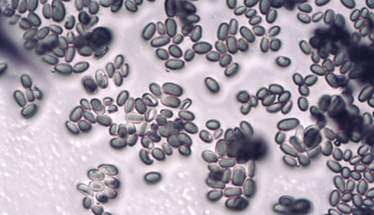

Scale insects are common pests of cannabis.

Are current analytical techniques up to the challenge?

CH: I would say so. Part of the difficulty is that there’s no synchronicity between the states. In my state of Massachusetts, we’re required to test for nine pesticides only. We currently test for 55 pesticides, but I’ve lost clients because they only want to test for the nine that are mandated. I think the regulations that have been established for the state of California are going to be the most stringent and most sensible that we’ve seen so far. It’s a fine line: if testing regulations are too onerous, people will find their way around them; if they are too expensive, that cost will be passed on to consumers and patients – and that’s when the black market rises.

DE: At CW, we’re just bringing our GC triple quad online. Historically, the LC triple quads have served us very well – it’s been our bedrock – but there are compounds on the regulator’s list that we simply can’t find very effectively with LC. Where pesticide detection is concerned, most of the technologies are “tried and true”. We’re now trying to exploit that knowledge base to better inform our own method development. Naturally, we would all love to have the “magical science box” our clients tend to imagine, which can test for everything! But, in truth, whenever I’ve seen a catch-all method on a single instrument, it always suffers some deficiency.

Aphids give birth to live young and spread quickly.

How do you see pesticide residue analysis developing in future?

CH: I think in 5–10 years, pesticide testing in cannabis will be no different than that performed in agriculture. The rapid growth of the cannabis industry is spurring innovation like nothing I’ve ever seen before. For example, the pharmaceutical industry has seen little improvement in child-proof packaging for decades. Now, thanks to the cannabis industry, the advances in child-proof packaging are astounding. As for analytical instrumentation, we work with a lot of instrument vendors who create prototypes of equipment, and what I see on the horizon for novel technologies is fascinating. LC/MS and GC/MS are not going to go away, but I think there are going to be better, cheaper alternatives in the next few years, driven by the complexity of pesticide testing. For example, the chemical sensors used for homeland security can sniff out chemical profiles with great sensitivity, and I think we’ll see them being applied to the cannabis industry. We have been working with many instrument vendors, including 908 Devices on the development of their 3-in-1 Cannabis Analyzer – another potential game changer in terms of speed of analysis, though it can’t detect pesticides at this time.

DE: I think we’ll see some “evening out” of the regulations. We’re always hoping for a standard method to be published, which every lab could follow and have faith in, and I hope we’ll see some homogeneity develop between states in time. But with each state driving its own regulations, it’s hard to say exactly when…

JW: I would definitely like to see more collaboration among instrument manufacturers, testing labs and regulatory bodies – as well as scientific communities – to develop more reliable methods, and standardize them to better serve our customers’ need for safe cannabis products. I’m hopeful that the AOAC and similar scientific organizations will be able to agree standardized methods for multi-residue pesticide analysis and organize meaningful inter-laboratory testing and validation or proficiency testing.

Spider mites are one of the most dreaded pests for growers.

It seems there is a real need for collaboration. Can you elaborate?

CH: There are many collaborative groups in the cannabis testing space, including AOAC for agriculture, AOCS for consumable oils like vegetable oils, ASTM for standards and testing, and, most critically for us, the US Pharmacopeia. I work on committees that are establishing testing protocols because I want synergy to exist between standards set by different organizations. Cannabis labs have extensive testing histories and experience, and I want to make sure we use that knowledge to create standards that are not only geared towards protecting consumer safety, but also make it feasible for the industry to survive.

DE: There is a lot of collaboration taking place between various labs, much of which is a direct result of the regulatory draft in California. The federal prohibition on shipping cannabis material makes it very difficult for laboratories to collaborate across state lines, so most of our collaboration has been within California, but we would love to work with groups and instrument manufacturers outside of the state. A few years back, Robert Martin began the ACCL (Association for Commercial Cannabis Labs) as an industry trade group, and that got labs talking to each other. We have an ACCL working group for pesticides, which includes several labs, instrument manufacturers, standards producers, and representatives from state agencies – we want to pool our knowledge to help fine tune our method development.

JW: With nationwide legalization of recreational cannabis expected in Canada this year, the demand for clean and safe cannabis products has grown significantly – and with it, the need for closer collaboration. PerkinElmer has invested heavily in the analytical testing of chemicals in cannabis; we’ve not only focused on high-quality instrumentation, but also on talented scientists who can work with our customers and partners to develop the best methodologies. For example, I worked recently with leading scientists within PerkinElmer, including Erasmus Cudjoe and Avinash Dalmia, as well as scientists from our partner SC Labs in California, to develop methods to meet the more stringent requirements of the Californian regulation for pesticide residues. An improved LC-MS/MS method – capable of determining all of the 72 pesticide residues in cannabis regulated by both California and Oregon State – has been developed as a result and will be presented at this year’s ASMS conference.

Of course, other companies, contract labs and regulatory agencies are also actively working on the pesticides project. At the 131st AOAC Annual Meeting there was a Cannabis Working Group, chaired by Susan Audino. This group is now calling for experts to join the review panel (see details below).

CH: Vendors are conducting huge amounts of research, because they want to further their instrumentation. It is very exciting to finally see significant investment in this area, and we’re working in partnership with multiple vendors. The challenge that most vendors have is that they cannot work with cannabis in their facility, so we provide the space, the product and the access, and they work with our chemists. It’s a nice synergy.

As well as feeding on the plant, mealybugs produce a sugary residue that can attract mold.

Final thoughts?

DE: Over the years, we’ve seen major improvements from a number of our clients, and have seen overall failure rates drop from 70 percent to below 50 percent. We’ve also seen increased awareness of the issue from producers of cannabis oils and edibles, who are driving demand for clean product in both directions – downward to the growers, and upwards to the end users. It’s not uncommon for dispensaries to display the Certificate of Analysis (COA) that we generate on the shelves next to their products.

CH: Ultimately, this is all about ensuring consumer safety. We work directly with a lot of patients, and our youngest was 13 months old when we started working with her. She has pediatric epilepsy, and my hope is that cannabinoid therapy will continue to control her seizures for decades to come. For long-term patients like her, it’s critical that these products are free from contamination.

AOAC International and the Cannabis Working Group is now calling for submissions of methods in cannabis analysis and for experts in this area to join the expert review panel or working group. Please contact [email protected] or visit goo.gl/T8WzAU to sign up. If you have a method that meets or exceeds the minimum requirements, please submit on the AOAC.ORG website.

Reference

PerkinElmer, “Analysis of pesticide residues in cannabis regulated by Oregon State using LC/MS/MS”, (2017). Available at: bit.ly/2rWArXM. Accessed February 1, 2018.

Disclaimer

The above opinions and comments from Jingcun Wu are his own, and do not represent the views of PerkinElmer.

Origin Stories

Our gurus tell us about their first steps into cannabis science.

Christopher Hudalla

I left Waters Corp to establish ProVerde because I could see that there was a need for robust and reliable testing in the cannabis industry, but I’ll admit I was terrified. I’d been doing research in industry and academia for 25 years, and I believed I was severing my ties with the professional scientific community. Ironically, the exact opposite happened; the move strengthened my network and I garnered a lot of respect from my colleagues, who now understand the potential for research and the need for safety testing.

I set up ProVerde around the time that Massachusetts started its medical cannabis program, and I made a case to regulators that testing is critically important to patient/consumer safety. Back then, no state had testing programs, but I found articles from peer-reviewed journals that documented cases of fatal or serious adverse events after consumption of cannabis tainted with pesticides, heavy metals, mycotoxins, residual solvents or microbiological contaminants. Officials were convinced, and mandated testing for various contaminants – every state that has legalized cannabis since then has included testing as part of their requirements.

David Egerton

My first introduction to pesticide analysis was during my graduate studies, when I worked on bioremediation of the herbicide atropine. From there, I was recruited by a long-time friend in California to help him start up an in-house QA/QC laboratory for a cannabis nursery. When CW Analytical started in 2009, it was literally just two guys in a garage with a GC – the old Silicon Valley story. Since that point, we’ve come a long way and we now work with SCIEX triple-quad LC and Thermo Fisher Scientific triple-quad GC systems.

Jingcun Wu

When I joined PerkinElmer, I not only had the opportunity to work with Sharanya Reddy and other scientists at PerkinElmer with an interest in cannabis analysis, but also with scientists Ben Armstrong and Carl Carnagey from our partner – Juniper Analytics LLC. Together, we developed a LC-MS/MS method for analysis of the 59 pesticide residues in cannabis regulated by the state of Oregon, and I have been working in the field ever since.